1. Nzvimbo

Bhuku rino rinosanganisira magetsi anoshandiswa, pneumatic inoshandiswa, hydraulic inoshandiswa uye mafuta-gasi inoshandiswa flanged yekubatanidza matatu-chidimbu akafukidzwa trunnion bhora mavharuvhu uye zvizere welded bhora mavharuvhu ane zita rezita NPS 8~36 & Kirasi 300 ~ 2500.

2. Chigadzirwa Tsanangudzo

2.1 Zvido zvehunyanzvi

2.1.1 Dhizaini uye Kugadzira mwero : API 6D, ASME B16.34

2.1.2 Kupera kusvika kumagumo ekubatanidza chiyero: ASME B16.5

2.1.3 Chiyero chehuso nechiso: ASME B16.10

2.1.4 The pressure-temperature giredhi mwero: ASME B16.34

2.1.5 Kuongorora uye bvunzo (kusanganisira hydraulic test): API 6D

2.1.6 Moto kuramba bvunzo: API 607

2.1.7 Sulfur kuramba kugadzirisa uye kuongorora zvinhu (inoshanda kune sour sevhisi): NACE MR0175/ISO 15156

2.1.8 Fugitive emission bvunzo (inoshanda kune yakavava sevhisi): sezviri BS EN ISO 15848-2 Kirasi B.

2.2 Chimiro chevhavha yebhora

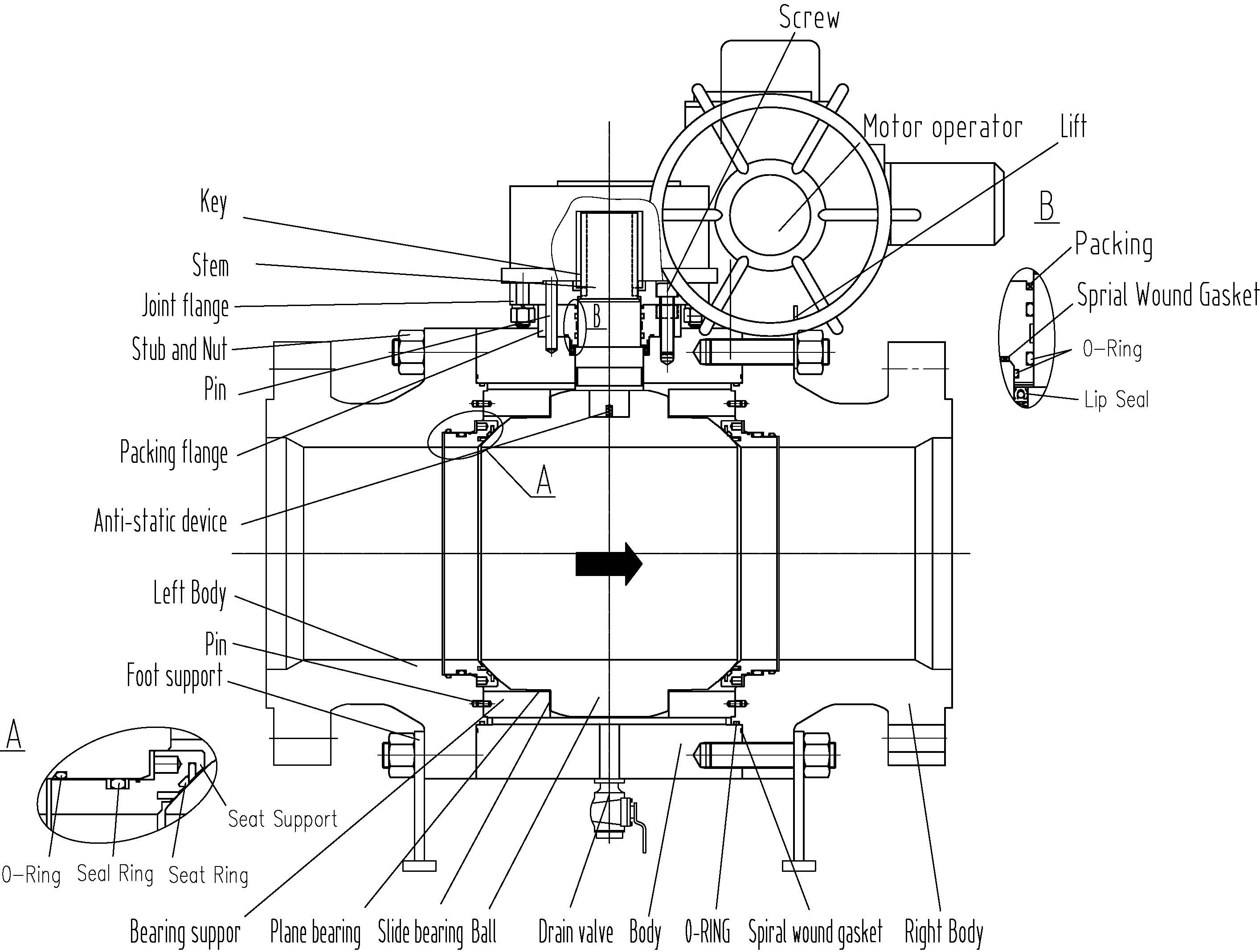

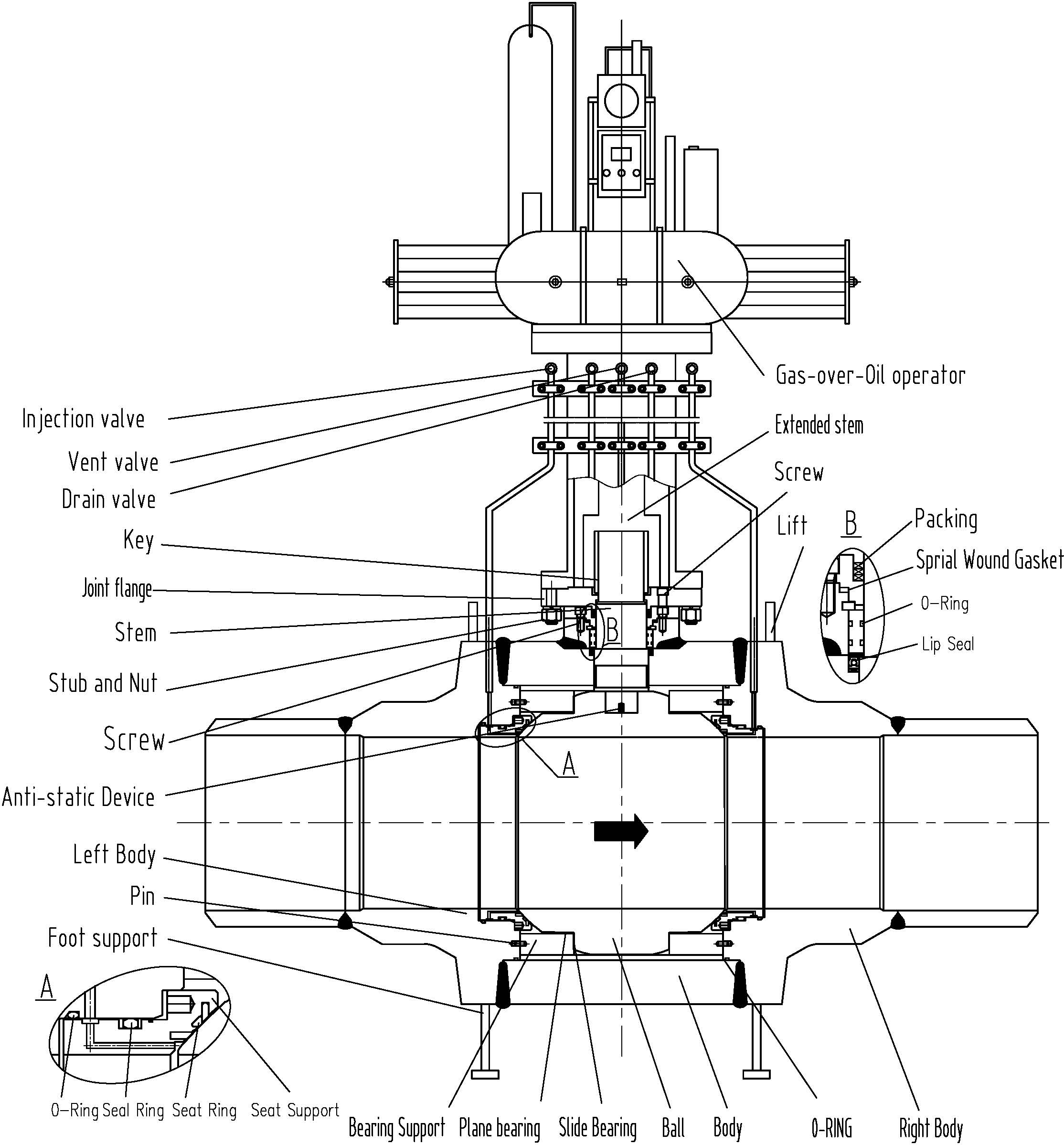

Figure1 Zvidimbu zvitatu zvakagadzira trunnion bhora mavharuvhu ane magetsi akaitwa

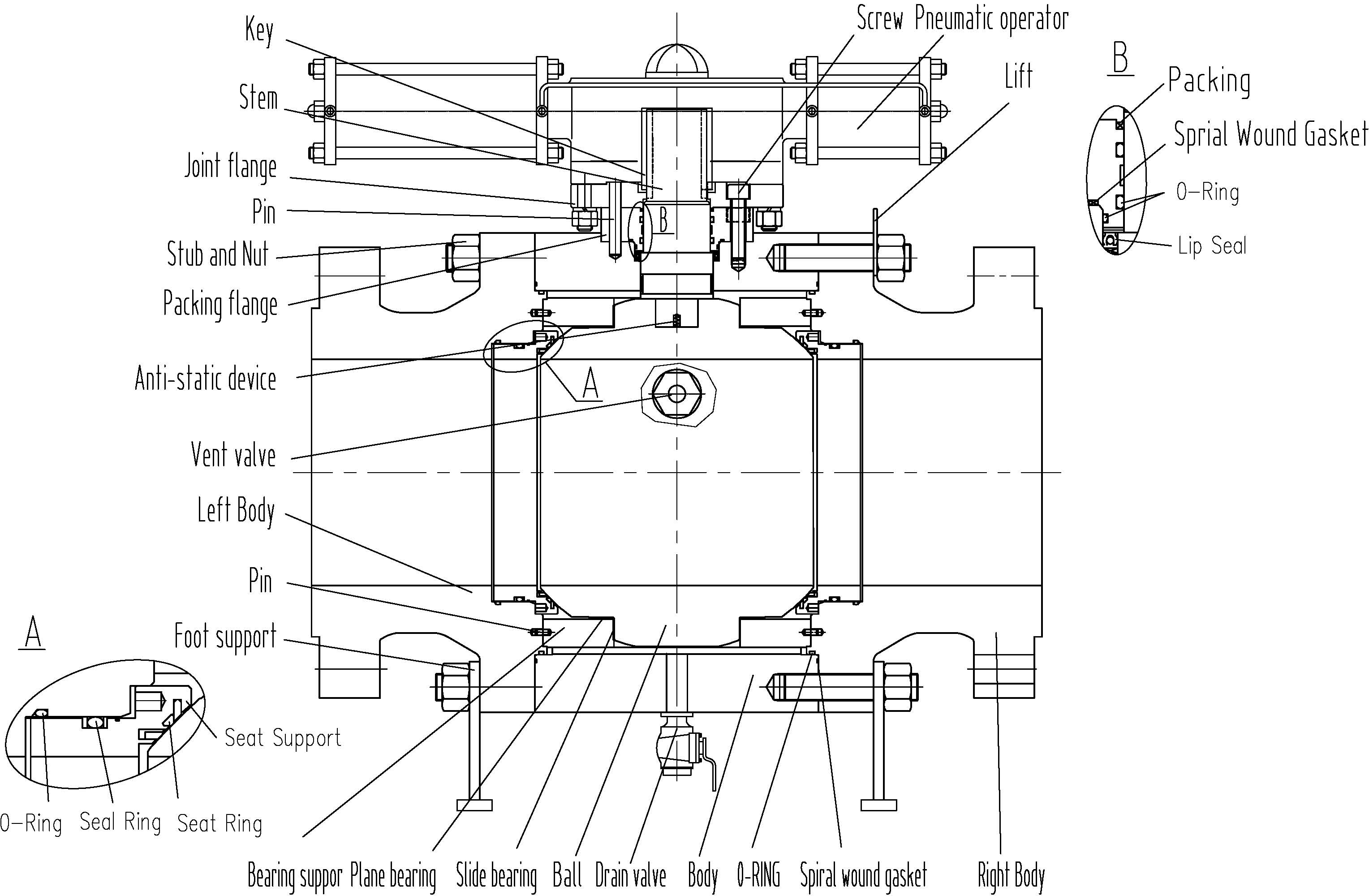

Mufananidzo2 Zvidimbu zvitatu zvakafogirwa trunnion bhora mavharuvhu ane pneumatic actuated

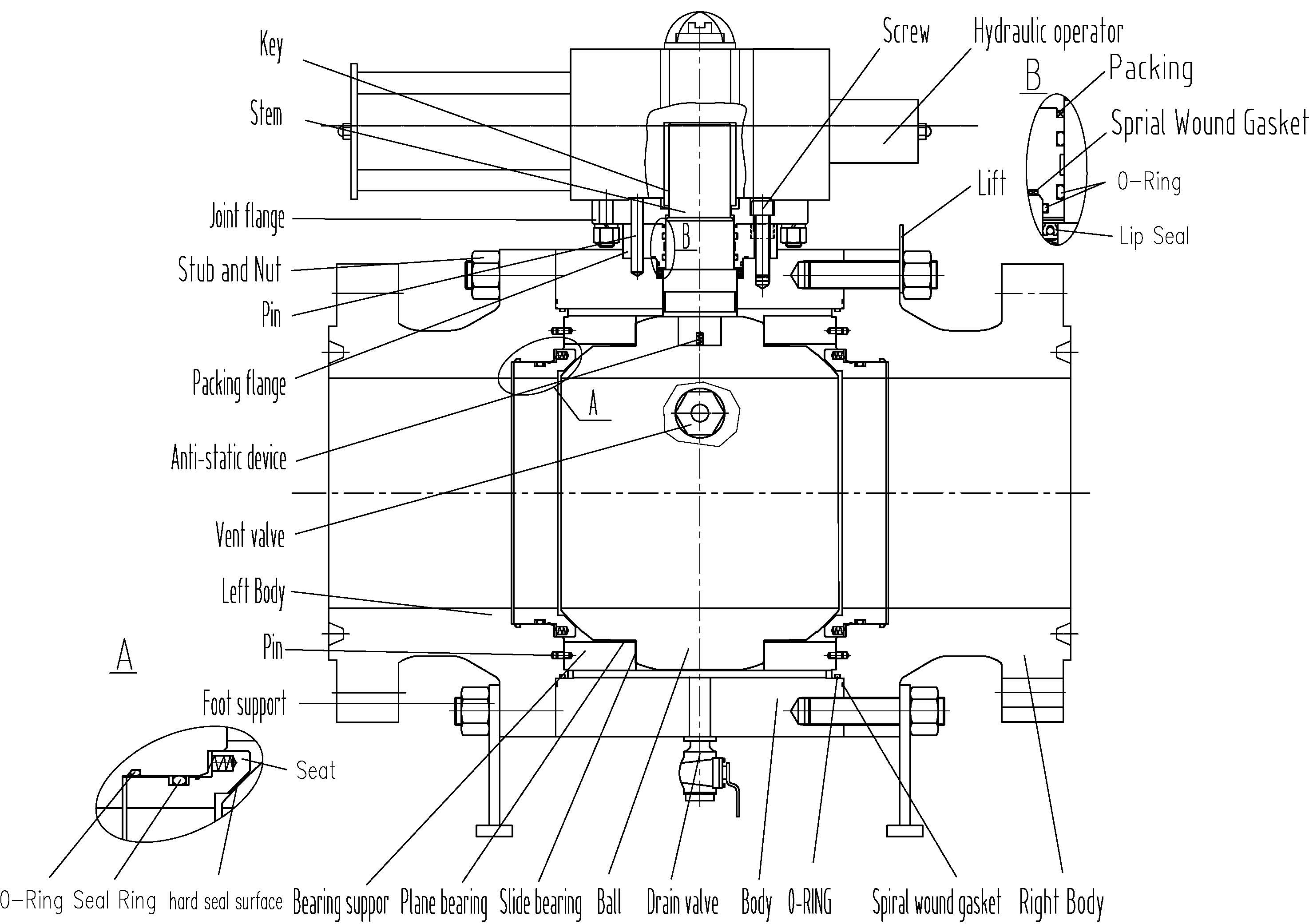

Mufananidzo3 Zvidimbu zvitatu zvakafogirwa trunnion bhora mavharuvhu ane hydraulic actuated

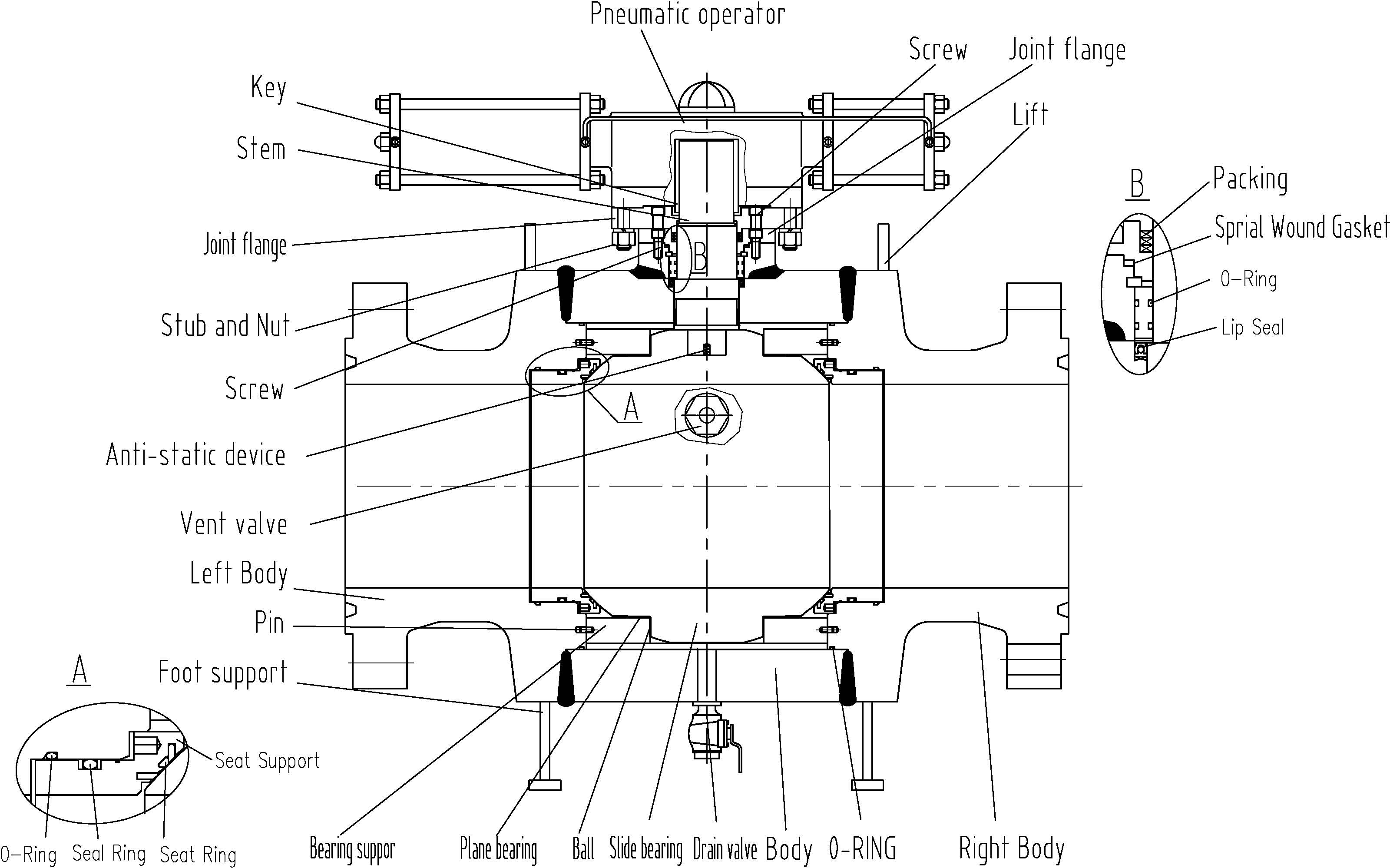

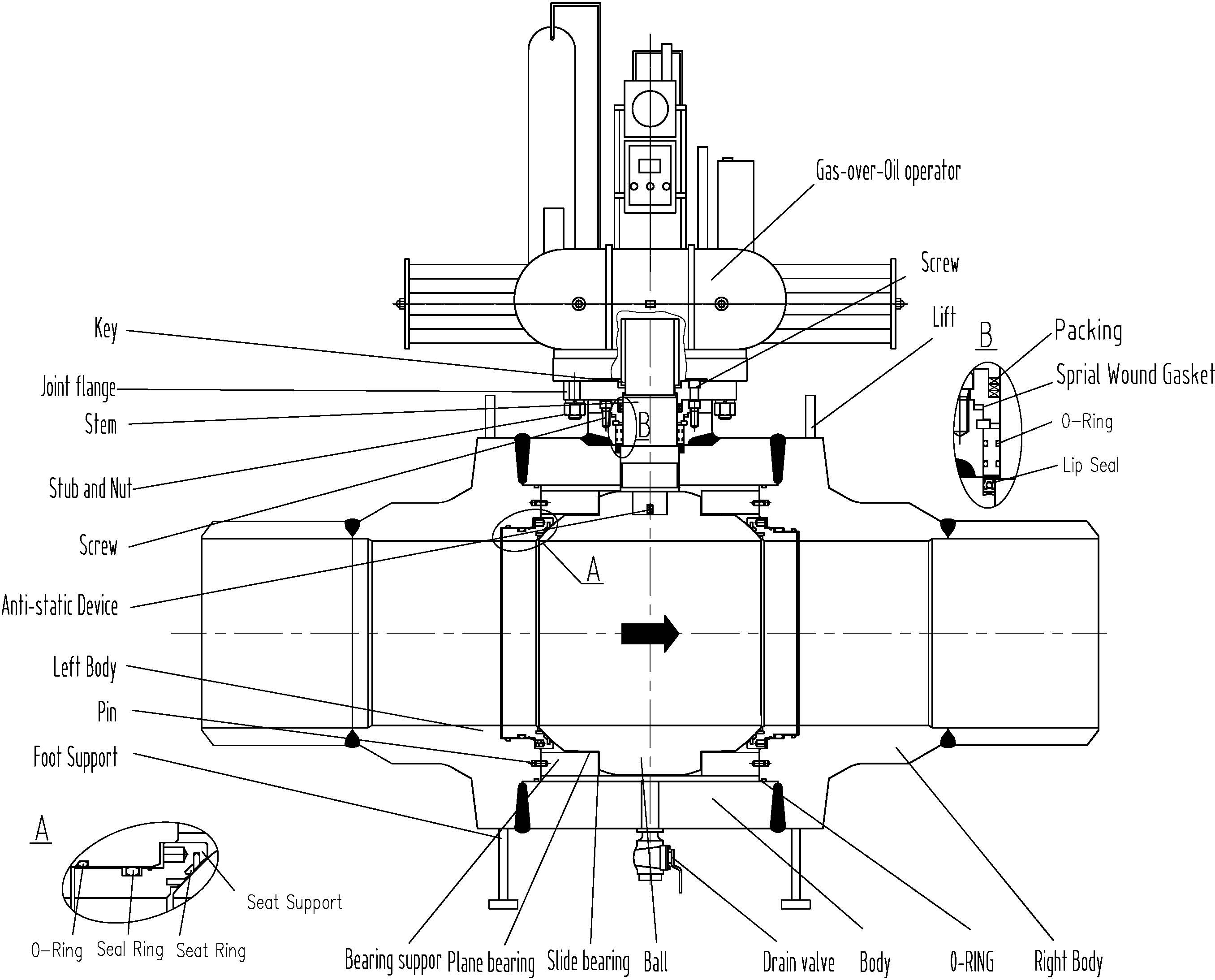

Figure4 Yakazara welded bhora mavharuvhu ane pneumatic actuated

Figure5 Yakavigwa yakazara yakakwenenzverwa bhora mavharuvhu ane oiri-gasi yakabatidzwa

Figure6 Yakazara welded bhora mavharuvhu ane mafuta-gasi actuated

3. Kuiswa

3.1 Pre-installation kugadzirira

(1) Mapaipi ese ari maviri ekupedzisira evharuvhu akagadzirira.Mberi uye kumashure kwepombi kunofanirwa kuve coaxial, maviri flange yekuisa chisimbiso nzvimbo inofanira kufanana.

(2) Mapombi akachena, tsvina ine girizi, siragi yewelding, uye mamwe matsvina ese anofanira kubviswa.

(3) Tarisa pakaiswa vharafu yebhora kuti uone mavharuvhu ebhora ari mumamiriro akanaka.Ivhavha ichavhurwa zvakazara uye yakavharwa zvizere kuratidza kuti iri kushanda nemazvo.

(4) Bvisa zvidziviriro zvinodzivirira mukubatana kwemagumo maviri evhavha.

(5) Tarisa kuvhurika kwevharuvhu wonyatsoichenesa.Nyaya yekune imwe nyika pakati pechigaro chevharuvhu / chigaro chemhete nebhora, kunyangwe kana granule chete inogona kukuvadza chigaro chevhavha chisimbiso kumeso.

(6) Usati waiswa, nyatso tarisa zita rezita kuti uone kuti rudzi rwevharuvhu, saizi, zvinhu zvechigaro uye giredhi rekumanikidza-tembiricha zvakakodzera kune mamiriro epombi.

(7) Usati waiswa, tarisa mabhoti ese uye nzungu mukubatana kwevhavha kuti ive nechokwadi chekuti yakasimbiswa.

(8)Kunyatsofamba mukufambisa, kukanda kana kudonha hakubvumidzwe.

3.2 Kuiswa

(1) Ivhavha yakaiswa pane pombi.Nezve media kuyerera zvinodiwa zvevharuvhu, simbisa kumusoro uye kudzika kwerwizi zvinoenderana negwaro revharuvhu ichaiswa.

(2) Pakati pevhavha flange uye pombi flange inofanira kuiswa magaskets maererano nezvinodiwa zvekugadzira pombi.

(3) Mabhaudhi eFlange anofanirwa kuenzana, anotevedzana, akaenzana kusimba

(4) Iyo butt welded yekubatanidza mavharuvhu anongozadzisa zvinotevera zvinodiwa kana aiswa welded kuti agadzirwe mupombi system panzvimbo:

a.Welding inofanirwa kuitwa neanowelda ane chitupa chekuwelder chinotenderwa neHurumende Boiler uye Pressure Vessel Authority;kana welder awana welder's qualification certificate yakataurwa muASME Vol.Ⅸ.

b.Welding process parameters inofanirwa kusarudzwa sezvakatsanangurwa mumhando yekusimbisa bhuku rewelding zvinhu

c.Iyo kemikari inoumbwa, mashandiro emuchina uye kushorwa kwesimbi yekuzadza simbi ye welding seam inofanirwa kuenderana ne base simbi.

(5) Paunenge uchisimudza nehombodo kana mutsipa wevhavha uye cheni inotsvedza yakasungirirwa pagumbo reruoko, bhokisi regiya kana zvimwe zvinogadzirisa hazvibvumirwi .Uyewo, kuguma kwekubatanidza kwevhavha kunofanira kubhadhara kudzivirira kubva pakukuvadzwa.

(6) Muviri we welded bhora vharafu unobva pabutt end weld 3 "chero nguva iri kunze kwekushisa kwekupisa hakufaniri kudarika 200 ℃. Usati waputira, matanho anofanirwa kutorwa kudzivirira kusvibiswa senge welding slag mumoto. kuwira mugero remuviri kana pakuisa chisimbiso.Pombi yakatumira inovanza kukora inofanira kutorwa kuyerwa kwekuomarara kwe weld.Kuomarara kwewelding seam ne base material hakupfuuri HRC22.

(7) Kana uchiisa mavharuvhu uye actuators, axis ye actuator worm inofanirwa kunge yakatarisana neaxis yepombi.

3.3 Kuongorora mushure mekuiswa

(1) Kuvhura nekuvhara 3 ~ 5 nguva yevhavha yebhora uye actuators haifaniri kuvharwa uye inosimbisa kuti mavhavha anogona kushanda zvakanaka.

(2) Chiso chekubatanidza cheflange pakati pepombi nevharuvhu yebhora chinofanira kutariswa mashandiro ekuisa chisimbiso zvinoenderana nezvinodiwa zvekugadzira pombi.

(3) Mushure mekuisa, iyo yekumanikidza bvunzo yehurongwa kana pombi, vharafu inofanira kunge iri munzvimbo yakazaruka zvizere.

4 .Kushanda, kuchengetedza nekugadzirisa

4.1 Ball valve ndeye 90 ° yekuvhura nekuvhara mhando, bhora revhavha rinongoshandiswa pakuchinja uye harishandiswe kugadzirisa!Hazvibvumirwi kuti vheji inoshandiswa mukupisa kwepamusoro uye muganhu wekumanikidzika uye nguva dzose kuchinjana kudzvinyirira, tembiricha uye mamiriro ekushanda ekushandiswa.The pressure-temperature giredhi ichave inoenderana neASME B16.34 Standard.Mabhaudhi anofanirwa kusimbiswa zvakare kana achinge adonha pakupisa kwakanyanya.Usabvumire kukanganisa kurodha uye chiitiko chekushushikana kwakanyanya hachibvumidze kuoneka pane yakaderera tembiricha.Vagadziri vacho havana basa kana tsaona ikaitika nekuda kwekutyorwa kwemitemo.

4.2 Mushandisi anofanira kuzadza mafuta ekuzora (girisi) nguva nenguva kana paine mavharuvhu egirisi ari erudzi rwelube.Nguva inofanira kuiswa nemushandisi maererano nehuwandu hwevhavha inovhurika, kazhinji kamwe chete pamwedzi mitatu;kana paine chero mavharuvhu egirisi ari erudzi rwechisimbiso, girisi yekuisa chisimbiso kana kurongedza zvinyoro kunofanirwa kuzadzwa nenguva kana vashandisi vakawana kuvuza, uye inoita shuwa kuti hapana kuvuza.Mushandisi anogara achigadzirisa michina iri mumamiriro akanaka!Kana pane mamwe matambudziko ehutano panguva yewaranti (maererano nechibvumirano), mugadziri anofanira kuenda kunzvimbo pakarepo uye kugadzirisa dambudziko racho.Kana inopfuura nguva yewaranti (maererano nechibvumirano), kana mushandisi achida kuti tigadzirise dambudziko, tinoenda kunzvimbo nekukurumidza uye kugadzirisa dambudziko.

4.3 Kutenderedzwa kwewachi kwemavharuvhu ekushanda kwemaoko kuchavharwa uye kutenderedzwa kwewachi kwemavharuvhu ekushandisa kuchavhurwa.Kana dzimwe nzira, bhatani rebhokisi rekutonga uye mirairo inofanirwa kuenderana nekuchinja kwemavharuvhu.Uye dzivisa kushanda kwakashata kunodzivisa kuitika.Vagadziri havana basa nekuda kwezvikanganiso zvekushandisa.

4.4 Mavharuvhu anofanirwa kugara achigadziriswa mushure mekunge mavharuvhu ashandiswa.Chiso chekuisa chisimbiso uye kuputika kunofanira kuongororwa kazhinji, sekuti kurongedza kuri kuchembera kana kukundikana;kana muviri ukaitika ngura.Kana mamiriro ari pamusoro akaitika, inguva yekugadzirisa kana kutsiva.

4.5 Kana iyo yepakati iri mvura kana mafuta, zvinokurudzirwa kuti mavharuvhu anofanirwa kuongororwa uye kuchengetedzwa mwedzi mitatu yega yega.Uye kana svikiro racho richiita ngura, zvinokurudzirwa kuti mavharuvhu ose kana chikamu chemavharuvhu chitariswe uye kuchengetedzwa mwedzi wega wega.

4.6 Bhora vharafu kazhinji haina thermal insulation chimiro.Kana iyo yepakati iri tembiricha yakakwira kana tembiricha yakaderera, pamusoro pevharuvhu haibvumidzwe kubata kudzivirira kubva pakupisa kana chando.

4.7 Pamusoro pemavharuvhu nedzinde uye zvimwe zvikamu zvinovhara zviri nyore huruva, mafuta uye utachiona hwepakati.Uye vharafu inofanira kuva abrasion uye corrosion nyore;kunyangwe inokonzerwa nekukweshana kupisa kunogadzira njodzi yegasi rinoputika.Saka vharafu inofanira kazhinji kuchenesa kuitira kuti ive nechokwadi chekushanda kwakanaka.

4.8 Kana mavharuvhu achigadziriswa nekugadzirisa, zvakafanana nehukuru hwepakutanga uye zvinhu o-mhete, gaskets, bolts uye nuts zvinofanira kushandiswa.O-mhete uye gaskets emavharuvhu anogona kushandiswa sekugadzirisa uye kugadzirisa zvigadziriso muhurongwa hwekutenga.

4.9 Inorambidzwa kubvisa ndiro yekubatanidza kuti itsive mabhoti, nuts uye o-rings apo valve iri mumamiriro ekudzvinyirira.Mushure mezvikwiriso, mabhaudhi, nzungu kana o-mhete, mavharuvhu anogona kushandiswa zvakare mushure mekuvhara bvunzo.

4.10 Kazhinji, zvikamu zvemukati zvevhavha zvinofanira kusarudzwa kugadzirisa uye kutsiva, zvakanakisisa kushandisa zvikamu zvevagadziri kuti zvitsive.

4.11 Mavhavha anofanira kuunganidzwa uye kugadziriswa mushure mekunge mavhavha agadziriswa.Uye dzinofanirwa kuongororwa mushure mekunge dzaunganidzwa.

4.12 Hazvikurudzirwe kuti mushandisi arambe achigadzirisa valve yekumanikidza.Kana zvikamu zvekumanikidza zvekugadzirisa zvakashandiswa kwenguva yakareba, uye njodzi inogona kuitika ichaitika, uye inokanganisa kuchengetedzwa kwemushandisi.Vashandisi vanofanira kutsiva vharuvhu itsva nenguva.

4.13 Nzvimbo yewelding yewelding mavharuvhu papombi inorambidzwa kugadzirisa.

4.14 Mavharuvhu ari papombi haatenderwi kubaya;ndeyekufamba uye sechinhu chipi nechipi chinorema pairi.

4.15 Migumo inofanira kuvharwa nenhovo muimba yakaoma uye ine mhepo, kuti ive nechokwadi chekuchena kwevhavhavhavha.

4.16 Mavharuvhu mahombe anofanirwa kutsigirwa uye haagone kubata pasi paanenge achichengetera kunze Zvakare, iyo isingapinde mvura-inoratidza hunyoro hunofanirwa kucherechedzwa.

4.17 Apo valve yekuchengetedza kwenguva yakareba inoshandiswa zvakare, kurongedza kunofanira kuongororwa kana kusina kukodzera uye kuzadza mafuta ekuzora muzvikamu zvinotenderera.

4.18 Mamiriro ekushanda evhavha anofanira kuramba akachena, nokuti anogona kuwedzera hupenyu hwayo hwebasa.

4.19 Ivhavha yekuchengetedza kwenguva yakareba inofanira kuongororwa nguva dzose uye kubvisa tsvina.Iyo yekuisa chisimbiso inofanirwa kutarisisa kuve yakachena kudzivirira kubva mukukuvadza.

4.20 Pekuro yepakutanga inochengetwa;pamusoro pemavharuvhu, stem shaft uye flange iyo yekuisa chisimbiso pamusoro peflange inofanirwa kuterera kudzivirira.

4.21 Iyo mhango yemavharuvhu haibvumidzwe kudonha kana kuvhura nekuvhara kusingasviki panzvimbo yakatarwa.

5. Matambudziko anogona kuitika, zvikonzero uye matanho ekugadzirisa (ona fomu 1)

Fomu 1 Matambudziko anogona kuitika, zvikonzero uye matanho ekugadzirisa

| Dambudziko tsanangudzo | Zvikonzero zvinobvira | Kugadzirisa matanho |

| Kudonha pakati pechiso chekuvhara | 1. Yakasviba yekuisa chisimbiso pamusoro2.Iyo yekuisa chisimbiso yakakuvadzwa | 1. Bvisa tsvina2.Gadzirisazve kana kuitsiva |

| Leakage pa stem packing | 1. Kurongedza kudzvanya simba hakuna kukwana2.Yakakuvadzwa kurongedza nekuda kwebasa renguva refu 3.O-mhete yekuputira bhokisi ndiko kukundikana | 1. Simbisa masiruuru zvakaenzana kuti ubatanidze packing2.Tsiva kurongedza

|

| Leak pakubatana pakati pevharuvhu muviri uye kuruboshwe -kurudyi muviri | 1.Kubatanidza mabhaudhi kutsanya kusaenzana2.Yakakuvadzwa flange chiso 3. Gaskets dzakakuvadzwa | 1. Zvakaenzana zvakasungwa2.Gadzirisa 3. Tsiva gaskets |

| Bvisa vharafu yegirisi | Marara ari mukati memavharuvhu egirisi | Geza nemvura shoma yekuchenesa |

| Yakakuvadza valve yegirisi | Isa uye kutsiva girisi yekubatsira mushure mekunge pombi yadzikisa kudzvanywa | |

| Bvisa mvura yevhavha | Yakakuvadza kuvhara kwevhavha yekudhonza | Kuiswa chisimbiso kwemavharuvhu ekudonha kunofanirwa kuongororwa uye kucheneswa kana kutsiviwa zvakananga.Kana yakakanganiswa zvakanyanya, mavharuvhu ekudonha anofanira kuchinjwa zvakananga. |

| Gear box/actuator | Gear box/actuator kutadza | Gadzirisa, gadzirisa kana kutsiva giya bhokisi uye actuator zvinoenderana negiya bhokisi uye actuator yakatarwa |

| Kutyaira kusachinjika kana bhora harivhure kana kuvhara. | 1. Bhokisi rekuputira uye mudziyo wekubatanidza uri skewed2.Dzinde nenhengo dzayo dzakuvara kana tsvina. 3. Nguva zhinji yekuvhura nekuvhara uye tsvina pamusoro pebhora | 1. Gadzirisa kurongedza, bhokisi rekutakura kana chigadziro chekubatanidza.2.Vhura, gadzirisa uye bvisa tsvina 4.Vhura, chenesa uye bvisa tsvina |

Ongorora: Munhu webasa anofanirwa kuve neruzivo rwakakodzera uye ruzivo nemavharuvhu

Nguva yekutumira: May-19-2022