1. Nzvimbo

Iwo maDN mitsara anosanganisira DN15mm~600mm(1/2”~24”) uye PN siyana kubva kuPN1.6MPa~20MPa(ANSI CLASS150~1500) yakarukwa, yakarukwa, BW uye SW swing uye yekusimudza cheki vharuvhu.

2.Kushandisa:

2.1 Iyi valve ndeyekudzivirira yepakati inoyerera ichidzokera kumashure mupombi system.

2.2 Valve zvinhu zvinosarudzwa zvinoenderana nepakati.

2.2.1WCB vharuvhu yakanakira mvura, chiutsi uye mafuta svikiro nezvimwe.

2.2.2SS vharafu inokodzera ngura yepakati.

2.3 Tembiricha:

2.3.1Common WCB inokodzera tembiricha -29℃ ~+425℃

2.3.2Alloy valve inokodzera tembiricha≤550℃

2.3.3SS vharafu inokodzera tembiricha-196 ℃ ~+200℃

3. Chimiro uye maitiro ekuita

3.1 Mamiriro ekutanga akaita senge pazasi:

3.2 PTFE uye flexible graphite inogamuchirwa kune inokuvadza gasket kuti ive nechokwadi chekuisa chisimbiso.

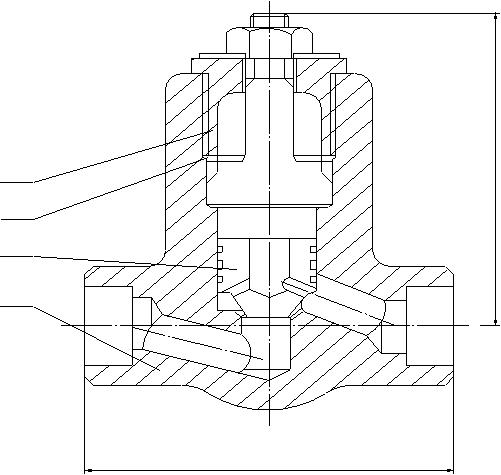

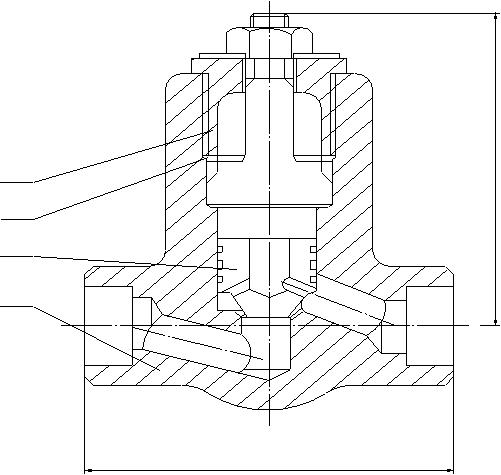

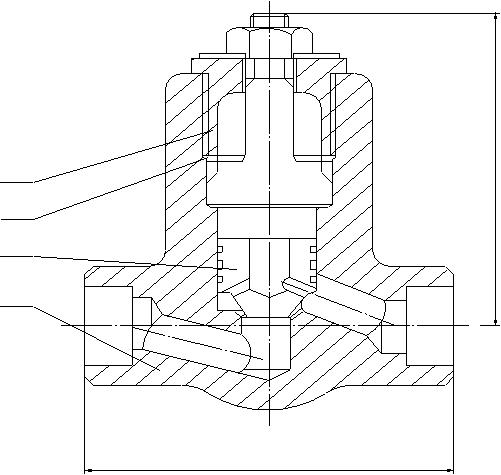

(A) Welding forged high pressure self-sealing lifting check valve

(B) Welding forged kusimudza cheki vharafu

1.muviri 2. disc 3. gasket 4. bhoneti

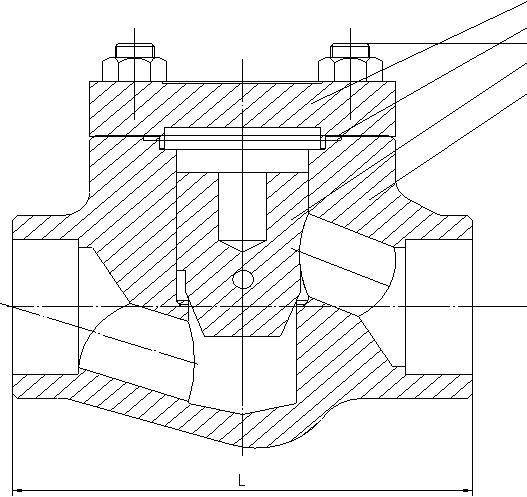

(C) BW Kusimudza Check Valve

(D) Flanged Check Valve

1.Muviri 2. Disc 3. Shaft 4. Gasket 5. Bhoneti

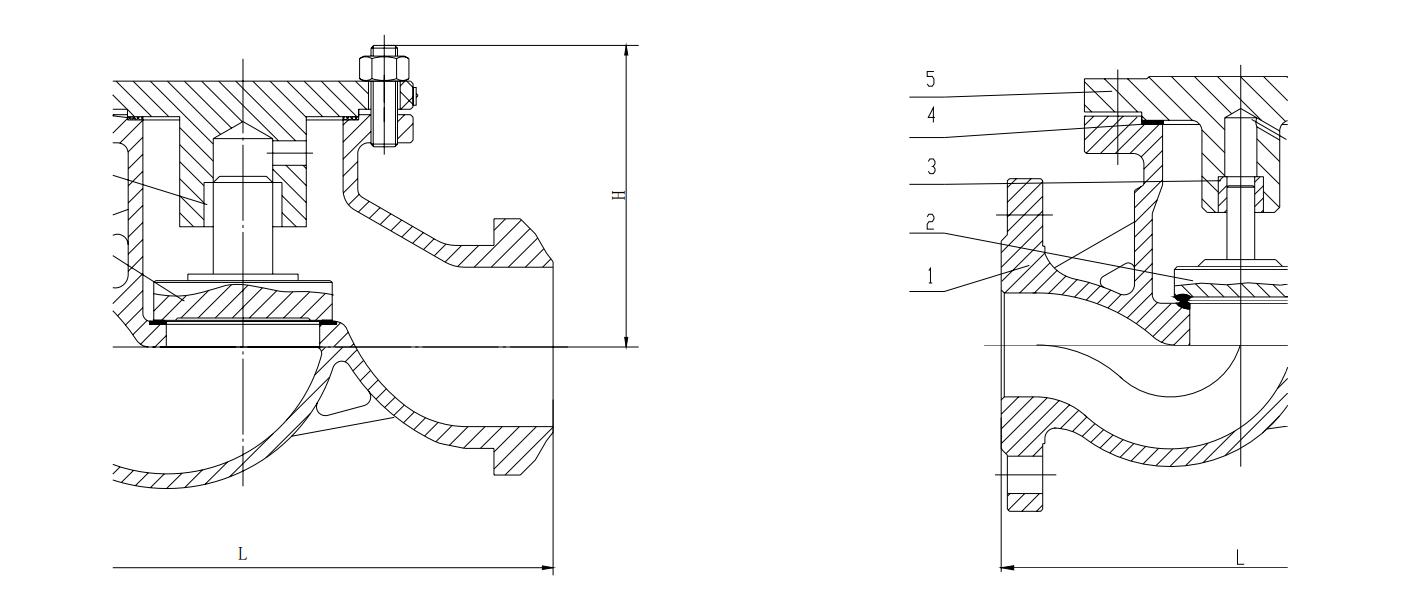

(E)BW Swing Tarisa Vhuru

(F) Flanged Swing Check

1.Body 2. Seat 3. Disc 4. Rocker Arm 5. Pin Shaft 6. Yoke 7. Gasket 8. Bonnet

3.3 Zvikamu Zvikuru Zvishandiso

| Zita | Material | Zita | Material |

| Muviri | Carbon Steel, SS, Alloy Steel | Pin Shaft | SS, Cr13 |

| Seat Chisimbiso | Surfacing13Cr, STL, Rubber | Joko | Carbon Steel, SS, Alloy Steel |

| Disc | Carbon Steel, SS, Alloy Steel | Gasket | PTFE, Flexible Graphite |

| Rocker Arm | Carbon Steel, SS, Alloy Steel | Bonnet | Carbon Steel, SS, Alloy Steel |

3.4 Performance Chart

| Rating | Muedzo wesimba (MPa) | Chisimbiso bvunzo (MPa) | Mhepo chisimbiso bvunzo (MPa) |

| Class150 | 3.0 | 2.2 | 0.4~0.7 |

| Class300 | 7.7 | 5.7 | 0.4~0.7 |

| Kirasi600 | 15.3 | 11.3 | 0.4~0.7 |

| Kirasi900 | 23.0 | 17.0 | 0.4~0.7 |

| Class1500 | 38.4 | 28.2 | 0.4~0.7 |

| Rating | Muedzo wesimba (MPa) | Chisimbiso bvunzo (MPa) | Mhepo chisimbiso bvunzo (MPa) |

| 16 | 2.4 | 1.76 | 0.4~0.7 |

| 25 | 3.75 | 2.75 | 0.4~0.7 |

| 40 | 6.0 | 4.4 | 0.4~0.7 |

| 64 | 9.6 | 7.04 | 0.4~0.7 |

| 100 | 15.0 | 11.0 | 0.4~0.7 |

| 160 | 24.0 | 17.6 | 0.4~0.7 |

| 200 | 30.0 | 22.0 | 0.4~0.7 |

4. Dzidziso yebasa

Cheki vharafu inovhura otomatiki uye inovhara dhisiki kudzivirira yepakati kuyerera kumashure nekuyerera kwepakati.

5. Miyero yevharuvhu inoshanda asi isina kuganhurirwa ku:

(1) API 6D-2002 (2) ASME B16.5-2003

(3) ASME B16.10-2000 (4) API 598-2004

(5) GB/T 12235-1989 (6) GB/T 12236-1989

(7) GB/T 9113.1-2000 (8) GB/T 12221-2005 (9) GB/T 13927-1992

6. Kuchengeta & Maintenance & Installation & Operation

6.1 Ivhavha inofanira kuchengetwa muimba yakaoma uye ine mhepo yakanaka.

6.2 Mavharuvhu ari pasi pekuchengetedza kwenguva refu anofanirwa kuongororwa uye kucheneswa nguva nenguva, kunyanya kugara kumeso kudzivirira kukuvara kwaro, uye chiso chekugara chinofanira kuputirwa ne ngura inodzivirira mafuta.

6.3 Kumaka vharafu kunofanirwa kutariswa kuti ienderane nekushandiswa.

6.4 Ivhavhavhavha uye yekuvharisa nzvimbo inofanirwa kuongororwa isati yaiswa uye kubvisa tsvina kana paine.

6.5Arrow direction inofanira kufanana negwara rekuyerera.

6.6 Kusimudza vertical disc cheki vharuvhu inofanira kuiswa yakatwasuka kune pombi.Kusimudza horizontal disc cheki vharafu inofanira kuiswa yakatwasuka kune pombi.

6.7 Kudengenyeka kunofanirwa kutariswa uye pombi yepakati pressure shanduko inofanirwa kucherechedzwa kudzivirira kuitika kwemvura.

7.Zvinetso zvinogoneka, zvikonzero uye chiyero chekugadzirisa

| Matambudziko Angabvira | Zvinokonzera | Chiyero chekugadzirisa |

| Diski harigone kuvhura kana kuvhara |

| |

| Leakage |

| |

| Noise uye Vibration |

|

8. Warranty

Mushure mokunge vharuvhu yaiswa mukushandiswa, nguva yewaranti yevhavha mwedzi gumi nemiviri, asi haipfuuri mwedzi 18 mushure mekusununguka.Munguva yewaranti, mugadziri achapa masevhisi ekugadzirisa kana zvisara zvemahara kukuvara nekuda kwezvinhu, kugadzira kana kukuvadzwa chero kuvhiya kuri iko.

Nguva yekutumira: May-19-2022