1. General

Rudzi urwu rwevharuvhu rakagadzirirwa kuve rakavhurika-uye-kuvharika kuisirwa kuchengetedza kushanda kwakakodzera kunoshandiswa mumaindasitiri pombi system.

2. Chigadzirwa Tsanangudzo

2.1 Chinodiwa chehunyanzvi

2.1.1 Dhizaini uye Manufacture Standard:API 600, API 602

2.1.2 Connection Dimension Standard:ASME B16.5 nezvimwe

2.1.3 Kutarisana Nekutarisana Dimension Standard:ASME B16.10

2.1.4 Kuongorora uye Muedzo: API 598 nezvimwe

2.1.5 Saizi: DN10 ~ 1200, Kudzvinyirira: 1.0 ~ 42MPa

2.2 Iri vharafu rakashongedzerwa nekubatana kweflange, BW yekubatanidza bhuku rinoshanda kukanda mavharuvhu egedhi.Dzinde rinofamba richienda kwakatwasuka.Gedhi disc rinovhara pombi panguva yekutenderera kwewachi kwevhiri reruoko.Gedhi dhisiki rinovhura pombi panguva yekutenderera kwewachi kutenderera kwevhiri reruoko.

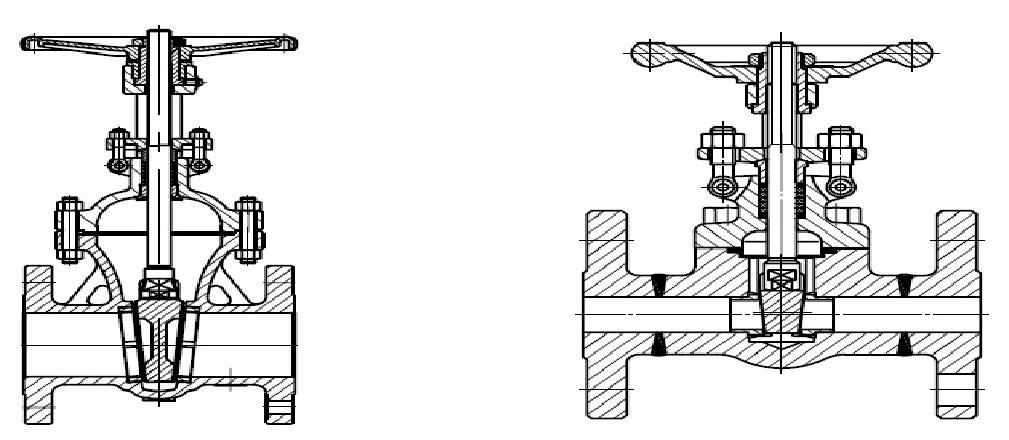

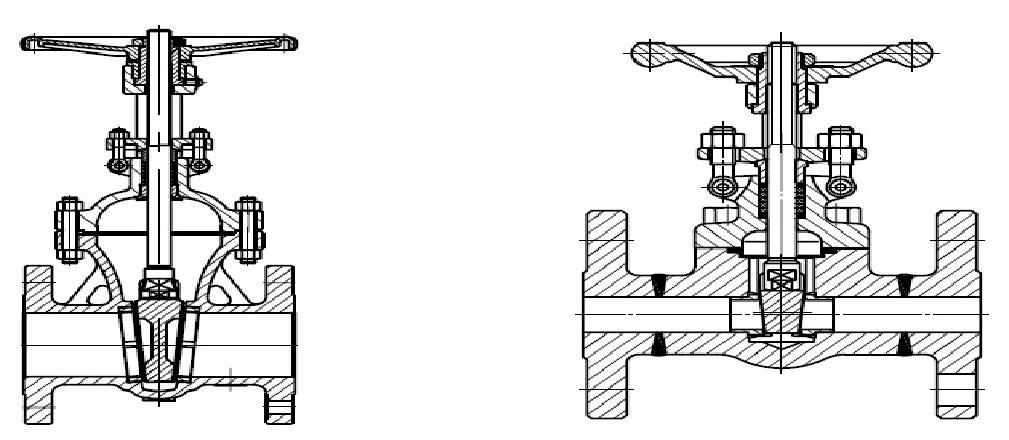

2.3 Ndokumbira utarise chimiro chemufananidzo unotevera

Kudhirowa 1

Dhirowa 2

Kudhirowa 3

Dhirowa 4

2.4 Zvikamu Zvikuru uye Zvinhu

| NAME | MATERIAL |

| Muviri /Bonnet | WCB,LCB,WC6,WC9,CF3,CF3M CF8,CF8M |

| Gate | WCB,LCB,WC6,WC9,CF3,CF3M CF8,CF8M |

| Seat | A105,LF2,F11,F22,F304(304L),F316(316L) |

| Stem | F304(304L),F316(316L),2Cr13,1Kr13 |

| Packing | Yakarukwa graphite & Flexible graphite & PTFE nezvimwe |

| Bolt/Nut | 35/25,35CrMoA/45 |

| Gasket | 304(316)+Grafiti /304(316)+ Gasket |

| Seat Mhete/Disiki /Kuisa chisimbiso | 13Kr,18Cr-8Ni,18Cr-8Ni-Mo,PP,PTFE,STL nezvimwe |

3. Kuchengeta & Maintenance & Installation & Operation

3.1 Kuchengeta & Kugadzirisa

3.1.1 Mavharuvhu anofanira kuchengetwa ari mukati memba.Iyo cavity inoguma inofanira kuvharwa neplug.

3.1.2 Periodic inspection and clearance inodiwa kwenguva yakareba yakachengetwa mavharuvhu, kunyanya pakuvhara nzvimbo yekuchenesa.Hapana kukanganisa kunobvumirwa.Oiri yekuputira inokumbirwa kudzivirira ngura yekugadzira machining pamusoro.

3.1.3 Nezvevhavhavha yekuchengetedza mwedzi inopfuura 18, miedzo inodiwa musati waiswa valve uye rekodha chigumisiro.

3.1.4 Mavharuvhu anofanirwa kuongororwa nguva nenguva uye kuchengetedzwa mushure mekuiswa.Pfungwa huru ndedzinotevera:

1)Kuisa chisimbiso pamusoro

2) Dzinde uye Stem nut

3)Kurongedza

4)Kucheneswa kwemukati kwepasi kweMuviri neBonnet.

3.2 Kuiswa

3.2.1 Ongororazve mavharuvhu (Type, DN, Rating, Material) izvo zvinoenderana nemakange akumbirwa nepipeline system.

3.2.2 Kucheneswa kwakazara kwegomba uye nzvimbo yakavharwa inokumbirwa pamberi pekuisa valve.

3.2.3 Ita shuwa kuti mabhaudhi akasimba usati waiswa.

3.2.4 Ita shuwa kuti kurongedza kwakasimba usati waisa.Zvisinei, haifaniri kukanganisa kufamba kwe stem.

3.2.5 Nzvimbo yevharuvhu inofanirwa kuve yakanakira kuongororwa uye kushanda.Horizontal kune pipeline inosarudzwa.Chengetedza vhiri reruoko kumusoro uye dzinde rakamira.

3.2.6 Kuvhara-vharavhavhavha, haina kukodzera kuiswa mumamiriro ekushanda kwepamusoro.Dzinde rinofanira kudziviswa kuti rikuvadzwe.

3.2.7 Kune Socket welding valve, kutarisa kunokumbirwa panguva yekubatanidza vharafu sezvinotevera:

1) Welder inofanirwa kuve yakasimbiswa.

2) Welding process parameter inofanirwa kuenderana nehukama welding material quality certificate.

3)Kuzadza zvinhu zvewelding mutsara, iyo kemikari uye mashandiro emuchina pamwe chete ne-anti-corrosion inofanira kufanana nemuviri wevabereki zvinhu.

3.2.8 Kuiswa kwevhavha kunofanirwa kudzivirira kudzvanywa kwepamusoro kubva kune zvakabatanidzwa kana pombi.

3.2.9 Mushure mekuisa, mavharuvhu anofanirwa kuvhurwa panguva yepipeline pressure test.

3.2.10 Support Point: kana pombi yakasimba zvakakwana kutsigira uremu hwevharuvhu uye torque yekushandisa, nzvimbo yekutsigira haina kukumbirwa.Zvikasadaro zvinodiwa.

3.2.11 Kusimudza: Kusimudza vhiri remaoko hakubvumidzwe kune mavharuvhu.

3.3 Kushanda uye Kushandisa

3.3.1 Mavharuvhu egedhi anofanirwa kuvhurika zvachose kana kuvharwa panguva yekushandiswa kudzivirira chigaro chekuisa chisimbiso mhete uye disc surface inokonzerwa nekumhanya kwepakati.Ivo havagone kumhan'arirwa nekuda kwekuyerera.

3.3.2 Gumbo remaoko rinofanira kushandiswa kutsiva zvimwe zviridzwa kuvhura kana kuvhara mavharuvhu

3.3.3 Munguva yekushisa kwesevhisi inobvumidzwa, kudzvanywa kwepakarepo kunofanirwa kunge kwakadzikira pane kudzvanywa maererano neASME B16.34

3.3.4 Hapana kukanganisa kana kurova kunobvumirwa panguva yekufambisa valve, kuisa uye kushanda.

3.3.5 Kuyera chiridzwa chekutarisa kuyerera kusina kugadzikana kunokumbirwa kudzora uye kubvisa iyo decomposition factor kudzivirira kukuvara kwevharuvhu uye kubuda.

3.3.6 Cold condensation ichapesvedzera mashandiro evharuvhu, uye midziyo yekuyera inofanira kushandiswa kuderedza kuyerera kwekushisa kana kutsiva vharafu.

3.3.7 Pamvura inozvipisa, shandisa midziyo yekuyeresa yakakodzera kuvimbisa ambient uye kushanda nesimba kusapfuudza nzvimbo yekuzvibatisa yega (kunyanya cherechedza kupenya kwezuva kana moto wekunze).

3.3.8 Kana paine mvura ine njodzi, yakadai sezvinoputika, zvinopisa, zvine muchetura, zvinogadzirwa neoxidation, hazvibvumidzwe kutsiva kurongedza pasi pekumanikidzwa.Zvakadaro, muchiitiko chekukurumidzira, hazvikurudzirwe kutsiva kurongedza pasi pekumanikidzwa (kunyangwe vharafu ine basa rakadaro).

3.3.9 Iva nechokwadi chokuti mvura haina kusvibiswa, iyo inokanganisa kushanda kwevharuvhu, kwete kusanganisira marara akaoma, kana zvisina kudaro midziyo yekuyera yakakodzera inofanira kushandiswa kubvisa tsvina uye yakaoma yakaoma, kana kuitsiva nemamwe marudzi evhavha.

3.3.10 Inoshanda tembiricha yekushanda.

| Material | Tembiricha | Material | Tembiricha |

| WCB | -29~425℃ | WC6 | -29~538℃ |

| LCB | -46~343℃ | WC9 | --29~570℃ |

| CF3(CF3M) | -196~454℃ | CF8(CF8M) | -196~454℃ |

3.3.11 Iva nechokwadi chokuti zvinhu zvemuviri wevharuvhu wakakodzera kushandiswa mukusaora uye ngura inodzivirira mvura.

3.3.12 Munguva yebasa, tarisa kushanda kwekuvharwa sekuenderana netafura iri pazasi:

| Inspection point | Leak |

| Kubatana pakati pemuviri wevharuvhu nebhoneti yevharuvhu | Zero |

| Packing seal | Zero |

| Valve body seat | Sekureva kwehunyanzvi hwekuita |

3.3.13 Gara uchitarisa kusapfeka kwemari yekugara, kurongedza kuchembera uye kukuvara.

3.3.14 Mushure mekugadzirisa, unganidza zvakare uye gadzirisa valve, wozoedza kushanda nesimba uye uite zvinyorwa.

4. Zvinetso zvinogona kuitika, zvinokonzera uye kugadzirisa matanho

| Dambudziko tsanangudzo | Zvikonzero zvinobvira | Kugadzirisa matanho |

| Leak pakurongedza | Kusakwana compressed packing | Simbisazve kurongedza nzungu |

|

| Kusakwana kuwanda kwekurongedza | Wedzera mamwe kurongedza |

|

| Yakakuvadzwa kurongedza nekuda kwesevhisi yenguva refu kana kuchengetedzwa kusina kunaka | Tsiva kurongedza |

| Leak pachiso chekugara kwevharuvhu | Huso hwekugara hwakasviba | Bvisa tsvina |

|

| Chiso chekugara chakasakara | Igadzirise kana kutsiva rin'i yechigaro kana ndiro yevharuvhu |

|

| Chiso chekugara chakakuvadzwa nekuda kwekuoma kwakasimba | Bvisa zvinhu zvakasimba mumvura, shandura mhete yechigaro kana ndiro yevharuvhu, kana shandura neimwe mhando yevharuvhu |

| Inodonha pakubatana pakati pemuviri wevharuvhu nebhoneti yevharuvhu | Mabhaudhi haana kusungwa zvakanaka | Uniformly sunga mabhaudhi |

|

| Yakakuvadzwa bhoneti yekuvharisa kumeso kwevharuvhu muviri uye vharafu flange | Gadzirisa |

|

| Yakakuvadzwa kana kuputsika gasket | Dzorera gasket |

| Kutenderera kwakaoma kwevhiri reruoko kana kuti valve plate haigone kuvhurwa kana kuvharwa. | Kunyanya kusungirirwa kurongedza | Zvakakodzera kusunungura kurongedza nati |

|

| Deformation kana kukotama kwegland yekuisa chisimbiso | Rongedza kuisa chisimbiso gland |

|

| Yakakuvadzwa vharafu stem nati | Ruramisa shinda uye bvisa yakasviba |

|

| Yakasakara kana kuputsika vharafu stem nati shinda | Tsiva vharafu stem nati |

|

| Bent valve stem | Tsiva hunde yevharuvhu |

|

| Dirty gwara pamusoro pevharuvhu ndiro kana muviri wevharuvhu | Bvisa tsvina panzvimbo yemutungamiri |

Cherechedza: Munhu webasa anofanira kunge ane ruzivo rwakakosha uye ruzivo nemavharuvhu Mvura inovhara gedhi vharafu

Iyo bhoneti yekurongedza imvura yekuisa chisimbiso chimiro, ichapatsanurwa kubva kumhepo nepo mvura inosvika pa 0.6 ~ 1.0MP kuvimbisa kuita kwakanaka kwekuvhara kwemhepo.

5. Warranty:

Mushure mokunge vharuvhu yaiswa mukushandiswa, nguva yewaranti yevhavha mwedzi gumi nemiviri, asi haipfuuri mwedzi 18 mushure mekusununguka.Munguva yewaranti, mugadziri achapa masevhisi ekugadzirisa kana zvisara zvemahara kukuvara nekuda kwezvinhu, kugadzira kana kukuvadzwa chero kuvhiya kuri iko.

Nguva yekutumira: May-19-2022